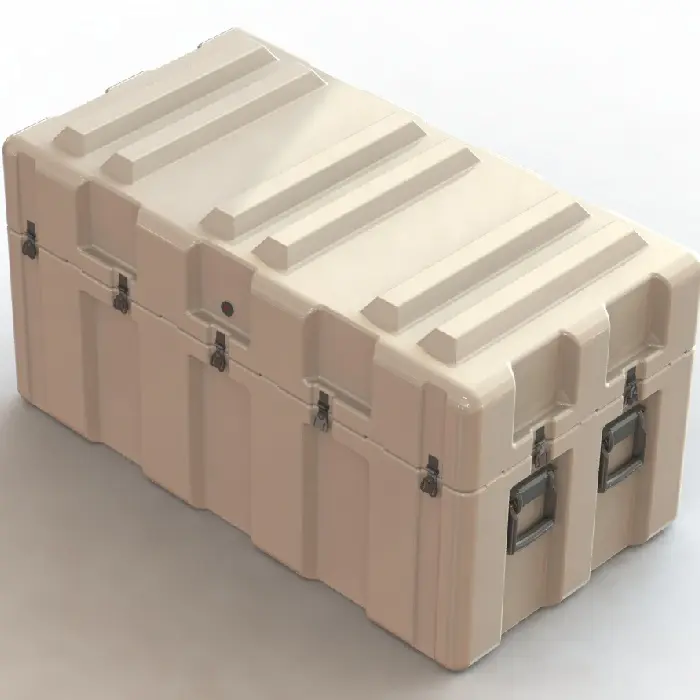

Carrying Cases – Blow Molded Cases – Blow Molded Carrying Cases

Ameripack is your source for Blow Molded Cases

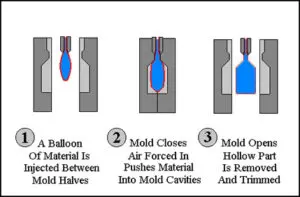

Blow molded cases offer the very best in state-of-the-art case design and technology. Blow molded casing creates a seamless, highly durable shell that protects your military or other sensitive equipment, as no other case manufacturing process can. A diagram at the bottom of this page shows more information on this process.

Ameripack’s line of Blow Molded Cases includes a variety of types, such as BMP Series Carrying Cases, Blow Molded Infinity Cases, and others.

See all the Ameripack Blow Molded Infinity Cases

See all the Ameripack Blow Molded Infinity Cases- See all the Ameripack Flambeau Brand Blow Molded Cases

- See all the Waterproof Blow Molded Cases

Ameripack BMP Carrying Cases: Stock, Semi-Custom, Custom – You Name It, We Have a Product for You!

Ameripack BMP Series carrying cases are easy to spot. The combination of light weight engineering along with attention to detail from design to finish make these cases unique on the market. Other features that make it unique? How about:

- The molded smooth edges reduce case damage

- Easy closing due to manufactured molding, superior clasps and casing

- 180° opening for easy accessibility. No other manufacturer compares to Ameripack.

- Irregular parting lines or techniques? A piece of cake for Ameripack

Why are blow molded cases superior?

Blow molded cases are formed by blowing plastic into a metal mold. This process creates a case that is uniquely and uniformly durable by virtue of its seamlessness and the use of thermoplastics. For more information on this process, please see the diagram at the bottom of this page.

Thermoplastics are state-of-the-art polymers renowned for being long lasting. Lego is one manufacturer that has built their reputation on the use of thermoplastics. And Ameripack is another one. Mass produced glass products are also created using blow molding.

Blow molded cases from Ameripack allow you to store, carry and travel with your equipment with peace of mind. The blow molded thermoplastics used in Ameripack cases can easily make the following promises:

- Strength and resistance against impact

- Toughness in low temperatures

- Resistance to many toxins, chemicals, etc.

- Electrical insulation properties

- Flame retardant properties

To further protect your gear, Ameripack specializes in custom foam inserts that can be fitted or cut to match your product’s requirements down to the detail.

Please Contact us for more information.

Request Info or Quote

Don’t listen to us. Listen to them.

Featured Cases

Ameripack, Inc. Introduces Slide-Out, Stackable Electronic Racks

Another Innovative solution from Ameripack! Our new stacking feature is a simple addition to any of the Ameripack Excalibur Series of Slide-Out Rack Mount Cases.

See all the

See all the